Products ListProducts List

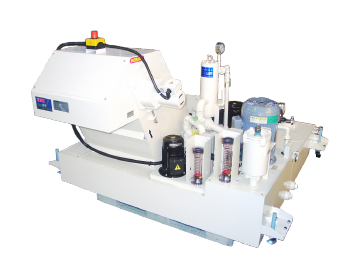

Primary / Secondary Simultaneous Process Equipment (Primary / Secondary Filter)

Dirty liquid coming out of the processing machine is processed for even higher precision processing.

Filters out particles over 10μm.

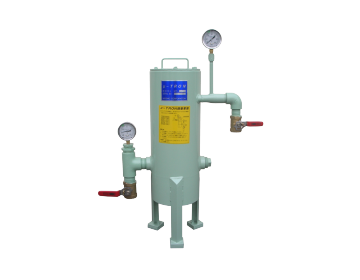

Primary Process Equipment (Primary Filter)

Processes dirty liquid drained from machine tools.

Filters out particles over 30μm.

Secondary Processing Equipment (Secondary Filter)

Further processes liquid processed already at primary stage.

Filters out particles over 10μm.