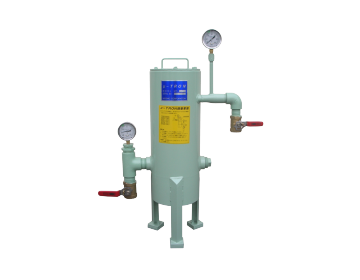

Cyclone filter [ μ-TRON (MT) ] : Secondary Filter

-

No filter media required and zero industrial waste An environmentally effective secondary filtering deviceReduces coolant tank cleaning works to the absolute minimum to extend coolant life and reduce costs.

In addition, the μ-TRON circulation cycle can be used to clean the primary-stage clean tank. -

Features

- Centrifugal device by pump pressure

- ·Coolant pumped to the inner casing generates a cyclone effect.

- ·Centrifugal and gravitational forces separate dirty coolant into clean coolant and condensed dirty coolant.

- ·Filter Rating : 90% and 20μm over

- ·Centrifugal separation eliminates filter media.

- Inner components are stainless; thus no consummables parts are used.

Main Specifications

Models range from 30L/min to 500L/min. Single or multiple units can be used depending on filtering volume required. Units are equipped with bubble prevention mechanism.

MT (μ-TRON)

Basic Specification

| Filter Rating | 50μm·90% 30μm·90% 20μm·90% 10μm·90% |

|---|---|

| Filter Volume (liters/min) |

~500 ~1,000 ~2,000 ~3,000 ~3,500 ~6,000 |

| Coolant | Water soluble Oils |

Applicable Chip Shape Table

| Material | Shape | ||||

| Cutting | Polishing | Washing | |||

| Non Magnetic Materials |

50mm or Longer

50mm or shorter

Needle-Shaped

Floating Chips

After Primary Stage

|

Sludge | Grains | ||

|---|---|---|---|---|---|

| Magnetic Particles (Steel) |

50mm or Longer

50mm or shorter

Needle-Shaped

Floating Chips

After Primary Stage

|

Sludge | Grains | ||

| Magnetic Particles (FC) |

50mm or Longer

50mm or shorter

Needle-Shaped

Floating Chips

After Primary Stage

|

Sludge | Grains | ||

Sedimentary tank of fine sludge,

which is installed dirty coolant drain outlet of cyclone filtration.